Digitally enhanced, hands-on surgical training

With support from the AO Innovation Translation Center (AO ITC), AO Research Institute Davos (ARI) scientists are leveraging ARI’s patented optical tracking technology to develop a cost-effective, transportable, and digitally augmented solution for hands-on surgical training.

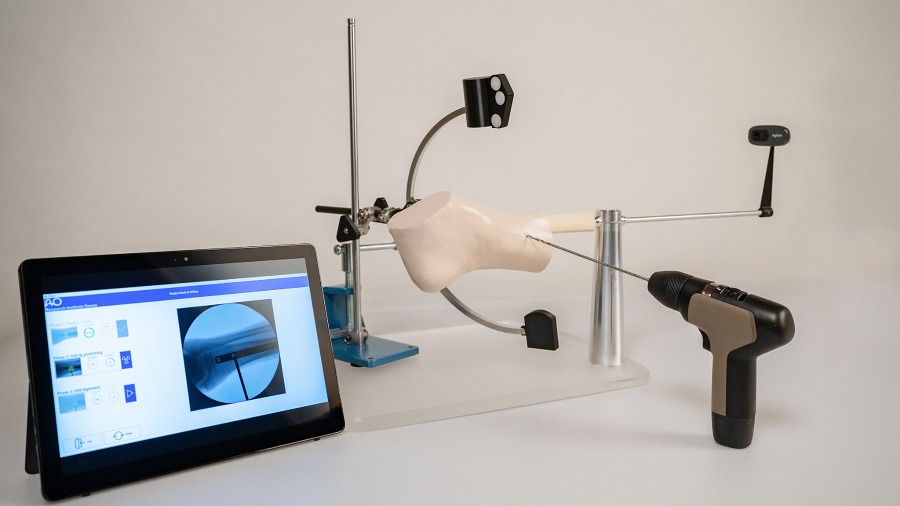

Fig 1 The digitally enhanced hands-on surgical training (DEHST) prototype will be demonstrated at the AO Davos Courses 2021.

Prototypes of a first module for surgical training on distal interlocking have received encouraging feedback from surgeons who have had the chance to test it. It is now in the product development stage and set for demonstration at the AO Davos Courses 2021. Supported by the AO Innovation Translation Center (AO ITC) strategy fund, the digitally enhanced, hands-on surgical training (DEHST) solution supplements hands-on education with an extended training scope and collates data for comprehensive evaluation, assessment, and potential certification.

The problem

Surgeons' practical skill and the ability to improve their surgical capabilities are key to the attainment of successful orthopedic and trauma surgery outcomes. Hands-on, tactile exercises are crucial to an effective training concept. Conventional hands-on training for the distal interlocking of intramedullary nails tends to be cost-intensive; typically offered only in course events; limited to a specific number of applications; and lacking substantial data collection to qualitatively evaluate and measure participant performance.

The solution

These limitations are solved by DEHST. It is a compact, cost-efficient, and mobile concept for hands-on training, offering a novel, mixed-reality training experience and enhanced training scope. A pilot module for distal interlocking of intramedullary nails features an artificial X-ray imaging engine that generates radiation-free simulated X-rays for a realistic training experience. Training can be tracked, and data can be collected and uploaded to the cloud. Users can access the data to get comprehensive training analytics and personalized skill assessment.

AO Research Institute Davos scientist Jan Buschbaum, PhD, senior project leader in ARI’s Concept Development Focus Area, is leading the 36-month project in collaboration with Markus Windolf, PhD, Focus Area Leader Concept Development.

The team aims to build a training station product line containing several modules for hands-on tutoring. For instance, the AO Skills Lab—an important hands-on surgical teaching experience—can be complemented by a new education platform using digital technologies to enhance the scope and track the training to provide the user with feedback in the form of performance metrics.

Based on an optical tracking technology invented and developed by Buschbaum and Windolf at ARI, the DEHST concept originated at the AO Davos Courses 2019 with discussions also involving Synbone AG and other relevant parties on how AO training could best be digitalized. The concept so far has the support of the AO’s Competence-Based Training and Assessment Program (CTAP) committee and can potentially be integrated into the CTAP educational framework as an intermediate learning tool for basic skills during early-stage training. Test users have expressed a clear need for such a tool.

The development team looks forward to gathering comprehensive user feedback at the AO Davos Courses 2021.

You might also be interested in

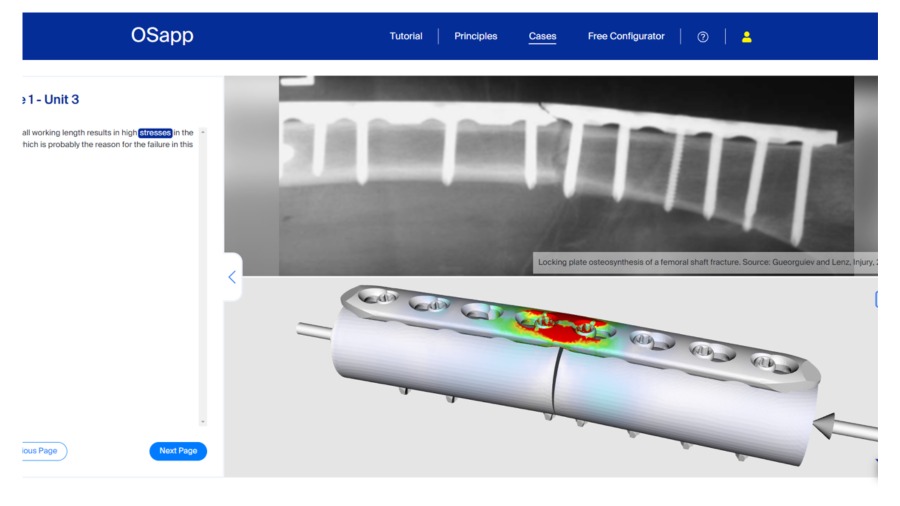

OSapp

A new, interactive, and constantly expanding virtual osteosynthesis software tool and interactive online learning platform.

AO Small External Fixator

The AO Small External Fixator is set for clinical documentation.

Technology Transfer of the AO fireside chat

AO Technology Transfer Board members Prof Anita Ignatius and Dr Robert Frigg say the AO is uniquely positioned to help innovators conquer those hurdles in order to improve patient care and outcomes.

Biphasic Plate

Improving fracture stabilization by providing a predictable mechanical environment at the fracture.