SmartFusion: Objective Monitoring of Spinal Fusion via AO’s Sensor Technology Can Enhance Spinal Care

Spinal fusion is a procedure permanently joining two or more vertebrae to eliminate movement between them, reduce pain and stabilize the spine. Today, spinal fusion monitoring relies mainly on CT imaging and patient-reported outcomes. While widely used, CT scans expose patients to radiation during follow up visits, provide only snapshots of the process, and depend on subjective interpretation.

What if the success of a spinal fusion could be monitored continuously, remotely, and without any radiation? What if spine surgeons could detect complications before they became critical – based on objective sensor data rather than relying on subjective image interpretation?

This vision is being explored in the AO Research Institute Davos (ARI), the AO Innovation Translation Center (ITC) and their partners through SmartFusion – a project to translate AO’s sensor technology for fracture healing monitoring (AO Fracture Monitor) into a novel approach to address spinal fusion.

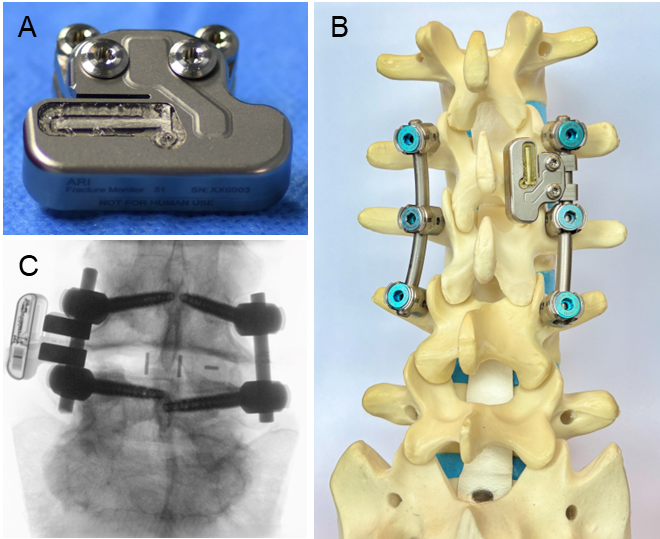

(Fig 1).

Figure 1: Fusion monitor sensor (A) attached via clamps to rods of an instrumented spine model (B). X-ray image (C) showing the sensor attached to the instrumentation in an anatomical specimen utilized to monitor the implant load after transforaminal lumbar interbody fusion in a biomechanical study [3].

From Fractures to Fusion: The Spark of an Idea

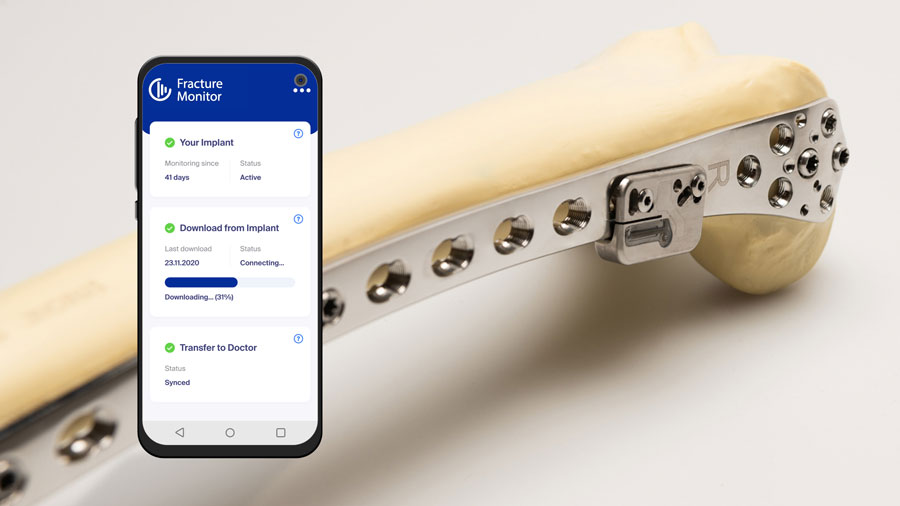

The AO Fracture Monitor was first developed as a system implementing an implantable sensor to track fracture healing in long bones. By continuously measuring the implant load of orthopedic plates during daily patient activities, the system is designed to allow remote assessment of fracture healing progression at any time – based on quantifiable data. The AO Fracture Monitor is currently part of a clinical safety study with the goal to be certified as a medical device following a successful clinical trial.

As the development advanced, a natural question arose: could this technology be applied to another challenging area of orthopedics – spinal fusion?

The possibility of offering objective, real-time and remote feedback on spinal fusion progression without any radiation would open the door to a transformative opportunity.

Testing the Concept

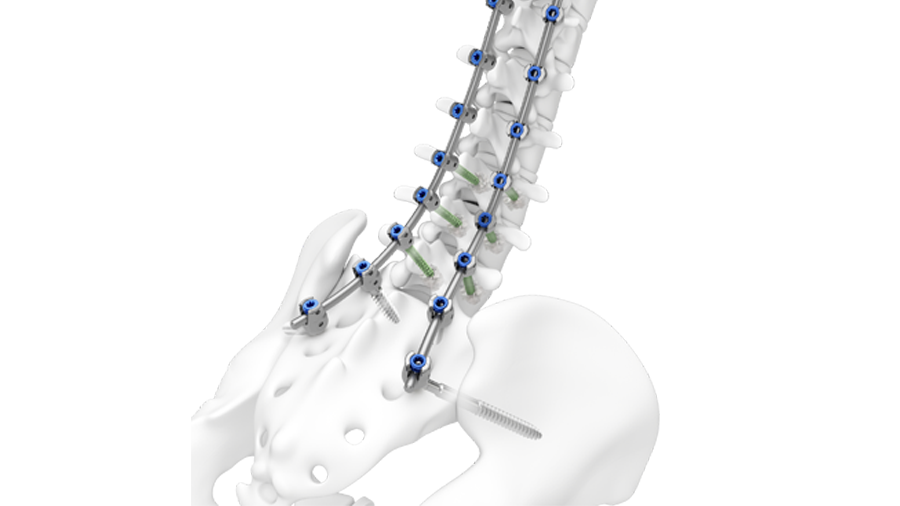

Utilizing the AO Fracture Monitor’s principle, the spinal fusion progression was assessed in ARI by measuring the load on implanted pedicle rod-screw systems. One major milestone was reached in a preclinical study, when an adapted version of the AO Fracture Monitor was successfully implanted in sheep – attached to posterior spinal instrumentation following posterolateral fusion surgery. Despite the in vivo complex loading scenarios, it was demonstrated that the continuously measured implant load decreased with ongoing fusion [1, 2].

The investigation was expanded to lumbar interbody and multilevel fusion procedures (Fig 1). Biomechanical studies were conducted in collaboration with the AO Technical Commission Spine to collect valuable data on both the potential and the limitations of the system [3, 4]. Particular emphasis was placed on the development of concepts to adapt the AO Fracture Monitor for spinal applications. Both preclinical and biomechanical studies supported the hypothesis that continuous implant load monitoring provides a reliable and objective measure of spinal fusion progression.

Building the Next Generation

With feasibility proven and a clear vision for the next concept, the project reached a turning point. Under the lead of Manuela Ernst (Senior Project Leader, ARI) and with support from the AO ITC, a roadmap was defined to bring the system closer to clinical reality.

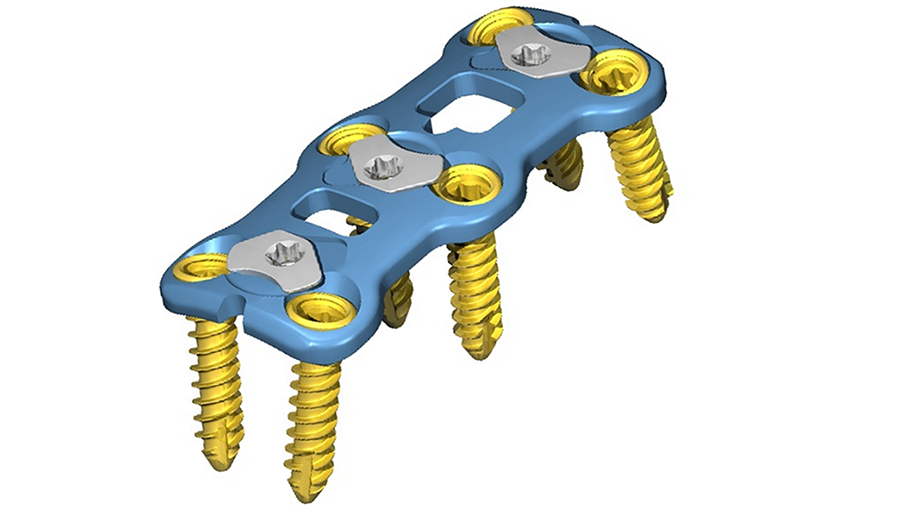

A new prototype, designed for spinal applications, is now under development. This next-generation system will meet the unique requirements of spine surgery, including optimized sensor size and sensitivity. Moreover, the new design will result in a platform technology, adaptable not only for spinal applications but also for use with other orthopedic implants and fixation systems.

To accelerate development, AO partnered with Sensirion AG (Stäfa, Switzerland) and secured an Innosuisse project grant in 2025. This collaboration is set to drive innovation from the lab to the operating room. In parallel, the project also explores the business model for such a system to help define the long-term future of the sensor technology.

A Glimpse into the Future

The vision of SmartFusion is ambitious. With a solid foundation of scientific proof and strong industry collaboration underway, SmartFusion has the potential to transform the monitoring of spinal fusion – shifting it from subjective snapshots to continuous, objective insights. Even though there is still work to be done, the project already exemplifies the AO’s spirit of innovation, translating visionary ideas into technologies that can advance patient care through collaboration between surgeons, scientists, engineers, and industrial partners.

References

- Windolf, M., et al., Continuous Rod Load Monitoring to Assess Spinal Fusion Status - Pilot In Vivo Data in Sheep. Medicina, 2022. 58(7): p. 899.

- Heumann, M., et al., Decreasing implant load indicates spinal fusion when measured continuously. Journal of Biomechanics, 2024. 163: p. 111929.

- Heumann, M., et al., Impact of transforaminal lumbar interbody fusion on rod load: a comparative biomechanical analysis between a cadaveric instrumentation and simulated bone fusion. Medical Engineering & Physics, 2025. 139: p. 104339.

- Heumann, M., et al., Impact of caudal segment bone fusion on rod load at the cranial segment in a two-level spinal interbody fusion construct- a biomechanical study. European Spine Journal, 2025. 34(9): p. 4024-4034.