VA-LCP Condylar Plate 4.5/5.0 in titanium alloy

Christoph Sommer, Rodrigo Pesantez

The VA-LCP Condylar Plate 4.5/5.0 is part of the VA-LCP Periarticular Plating system and has been designed to provide variability in screw trajectory. This allows surgeons to direct the locking screw at a specific angle to grab a specific fracture fragment or to bypass previously placed implants and respond to periprosthetic fractures.

The stainless steel version of this plate was introduced in 2011 and its design features are described in detail in the AOTK System Innovations magazine 2/2011. While stainless steel implants are mainly used in the USA, there is a preference for titanium alloy implants in Europe and Asia. The modulus of elasticity of titanium alloy is markedly lower than the one of stainless steel. This means that titanium alloy is less stiff compared to stainless steel and the elastic deformations on titanium implants are a closer reflection to that of bone. Although there are various aspects involved when selecting the implant material (eg, construct stiffness, allergic patient response, bone and soft tissue adhesion, ease of implant removal) there is no clinical evidence that one or the other implant material provides a clear clinical advantage with regard to patient outcome. The choice of the implant material therefore continues to be driven mainly by regional practice.

To complete the implant portfolio and to address the various surgical preferences with regard to implant material, a titanium alloy version of the VA-LCP Condylar Plate 4.5/5.0 has been developed that can be used together with the OPTILINK screw technology, as described under 'Details' below.

Benefits and features

The main benefit of the VA-LCP Condylar Plate 4.5/5.0 is the ability to place variable angle locking screws to create a fixed-angle construct while also providing the surgeon with the freedom to choose the most optimal screw trajectory according to the fracture pattern. This feature is also advantageous for placement of locked screws around femoral prostheses. Since placing screws at their nominal angle provides maximal connection strength between plate and screw, off-axis angles should only be chosen when clinically indicated.

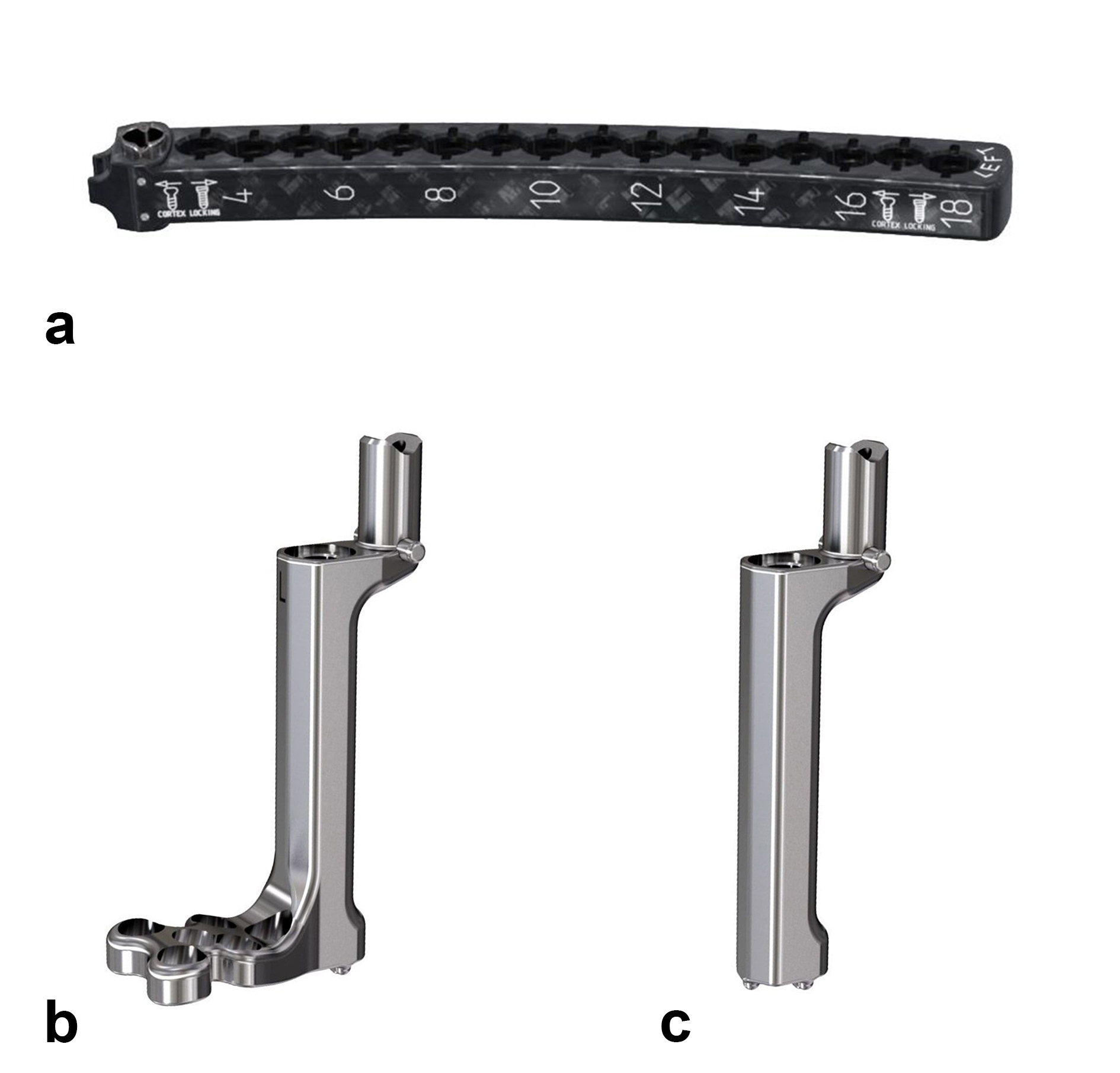

To increase bone anchorage in the presence of prostheses, locking attachment plates can be mounted to the VA combi-holes in the shaft component of the plate. Further periprosthetic treatment options include VA periprosthetic locking screws with blunt tip and VA positioning pins for cable system in cruciform design (Fig 1) to fit in the VA locking hole.

Screw types

The plate is compatible with several screw types, fulfilling diverse functions including use for locking, VA locking, and cortex screws:

- Every VA locking hole accepts VA locking screws; the central hole in the head of the plate is a fixed angle locking hole and accepts 5.0 mm VA locking screws in nominal angle

- Every VA locking hole and the central fixed angle plate head hole accepts non-VA locking screws; they must be inserted in nominal angle but it is recommended to use the available guiding tools to assist insertion in nominal angle

- 4.5 mm cortex screws can be used in the DCU portion of combiholes and the central plate head hole to compress the plate to the bone (increasing rotational stability) or create axial interfragmentary compression.

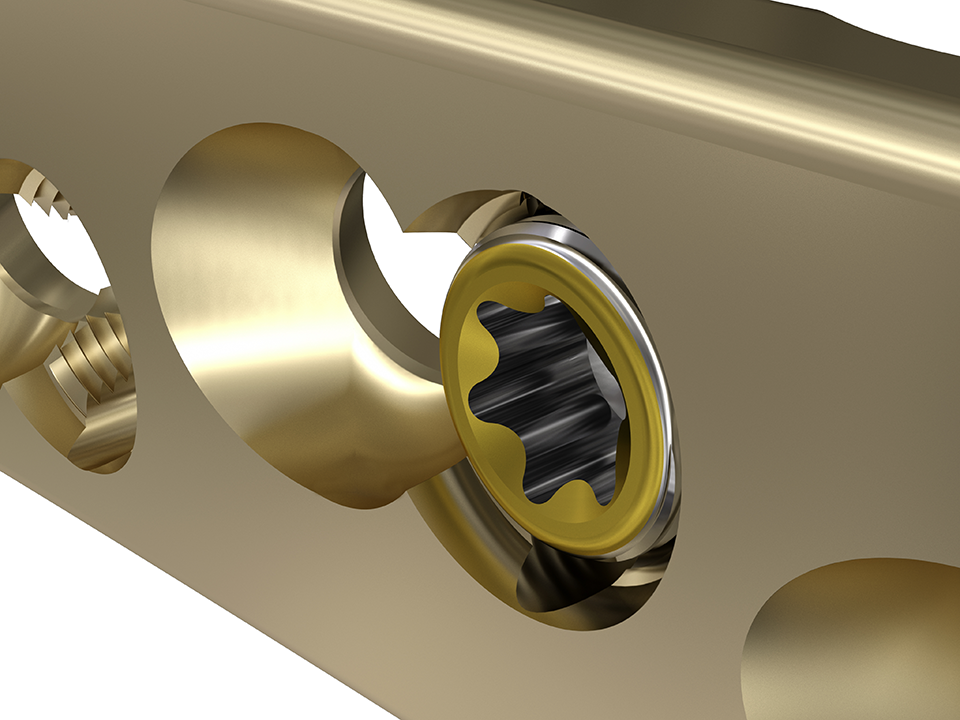

OPTILINK screw technology

Special VA locking screws in stainless steel that have undergone carburizing are required for the VA-LCP Condylar Plate 4.5/5.0 in titanium alloy. Carburizing is a low temperature heat treatment process (around 500 degrees Celsius) applied to metals in an environment enriched with carbon atoms. The metal surface absorbs carbon in the outer surface of the screw (33 μm layer thickness) and increases in hardness and strength. The brand name of this technology applied to stainless steel VA locking screws is called OPTILINK technology.

The advantages of screws with OPTILINK screw technology (Fig 2) are as follows:

- Safe mixing of a titanium alloy plate with a stainless steel screw due to equivalent corrosion resistance properties as nonmixed-metal plate-screw constructs made of stainless steel

- The plate-screw construct combines the stability and smoothness of stainless steel screws with OPTILINK technology with the elasticity of titanium alloy plates

- High stability at plate-screw interface due to increased surface hardness

- Reliable insertion and removal due to low deformation of the stardrive recess

- Potential for low cell adhesion characteristics that are comparable to stainless steel due to a similarly smooth surface topography as untreated stainless steel, which is beneficial for ease of screw removal.

The OPTILINK screw technology allows the use of stainless steel screws with titanium alloy plates without any potential drawbacks of mixing metals in fracture treatment. However, it is currently only applied for 5.0 mm VA locking screws, which are supposed to be used with the VA-LCP Condylar Plate 4.5/5.0 in titanium alloy.

Broad instrument options including minimally invasive instrumentation for limited soft-tissue trauma are provided for the plating system. There is one universal aiming arm for both left and right plates, which allows, together with dedicated instrumentation, minimally invasive targeted predrilling and screw insertion in the plate shaft. The universal aiming arm is supposed to be attached to insertion handles with or without guiding block (Fig 1). The insertion handle with guiding block (left and right versions) can be used for targeted predrilling and screw insertion in the plate head if this is beneficial.

Case provided by Christoph Sommer, Chur, Switzerland

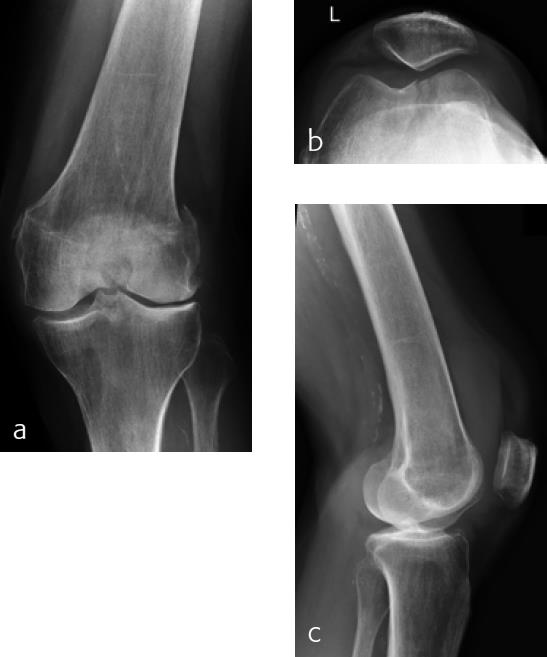

A 79-year-old woman fell downstairs at home and sustained a low-energy distal intraarticular femoral fracture. On conventional x-rays, the fracture seemed to be a unicondylar lateral split-type in rather osteoporotic bone (Fig 1). For detailed fracture analysis, a CT scan was performed that demonstrated a displaced lateral and nondisplaced medial condylar fracture (AO-33C1) (Fig 2). The fracture was very distal and therefore difficult to address with one lateral plate. Using VA technology in this situation provided the advantage of angulating the most distal anterior screw very close to the intercondylar notch in order to address the nondisplaced but fractured anteromedial condyle (Fig 3). Due to poor bone quality, a long plate was used to prevent a future periimplant fracture. Early follow-up showed uneventful healing with good function.

Hazards and labeling

Due to varying countries’ legal and regulatory approval requirements, consult the appropriate local product labeling for approved intended use of the products described on this website. All devices on this website are approved by the AO Technical Commission. For logistical reasons, these devices may not be available in all countries worldwide at the date of publication.

Legal restrictions

This work was produced by AO Foundation, Switzerland. All rights reserved by AO Foundation. This publication, including all parts thereof, is legally protected by copyright.

Any use, exploitation or commercialization outside the narrow limits set forth by copyright legislation and the restrictions on use laid out below, without the publisher‘s consent, is illegal and liable to prosecution. This applies in particular to photostat reproduction, copying, scanning or duplication of any kind, translation, preparation of microfilms, electronic data processing, and storage such as making this publication available on Intranet or Internet.

Some of the products, names, instruments, treatments, logos, designs, etc referred to in this publication are also protected by patents, trademarks or by other intellectual property protection laws (eg, “AO” and the AO logo are subject to trademark applications/registrations) even though specific reference to this fact is not always made in the text. Therefore, the appearance of a name, instrument, etc without designation as proprietary is not to be construed as a representation by the publisher that it is in the public domain.

Restrictions on use: The rightful owner of an authorized copy of this work may use it for educational and research purposes only. Single images or illustrations may be copied for research or educational purposes only. The images or illustrations may not be altered in any way and need to carry the following statement of origin “Copyright by AO Foundation, Switzerland”.

Check www.aofoundation.org/disclaimer for more information.

If you have any comments or questions on the articles or the new devices, please do not hesitate to contact us.

“approved by AO Technical Commission” and “approved by AO”

The brands and labels “approved by AO Technical Commission” and “approved by AO”, particularly "AO" and the AO logo, are AO Foundation's intellectual property and subject to trademark applications and registrations, respectively. The use of these brands and labels is regulated by licensing agreements between AO Foundation and the producers of innovation products obliged to use such labels to declare the products as AO Technical Commission or AO Foundation approved solutions. Any unauthorized or inadequate use of these trademarks may be subject to legal action.

AO ITC Innovations Magazine

Find all issues of the AO ITC Innovations Magazine for download here.

Innovation Awards

Recognizing outstanding achievements in development and fostering excellence in surgical innovation.