4.5 mm VA-LCP Curved Condylar Plate

Matthew Graves, Sean Nork

The 4.5 mm VA-LCP Curved Condylar Plate is part of the variable angle (VA) periarticular plating system that merges variable angle locking screw technology with conventional plating techniques. It was designed with a focus on creating a simpler implant that could be used for virtually all fracture, nonunion, and malunion indications in the distal femur, regardless of the complexity of the fracture pattern, the quality of the bone, or the presence of adjacent prostheses.

Variable angle technology

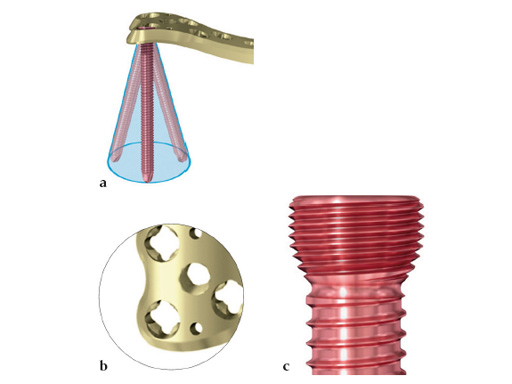

Five VA screw holes surround the central fixed-angle screw hole in the plate head (Fig 1). These allow the surgeon to place screws around stems and adjacent to distal femoral prostheses, achieving stability in worst-case scenarios. Screw holes in the shaft component of the implant are VA combination holes, allowing screw placement around proximal femoral stems or through endosteal implant holes. If a different screw trajectory is desired than can be obtained via the 30° cone of locked angulation (Fig 1a) or with a conventional 4.5 mm cortex screw, the locking periprosthetic attachment plate can be attached to the VA combination hole.

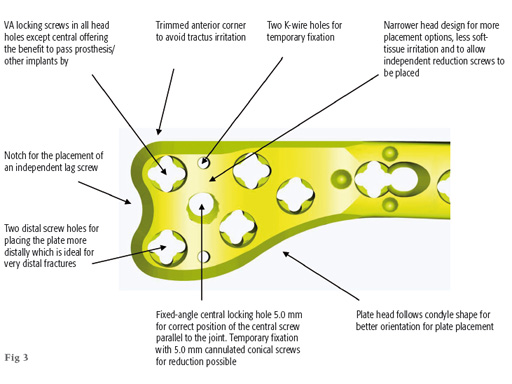

Further design advantages (Fig 2)

1. Smaller distal footprint with contoured edges to limit irritation of the iliotibial band. This smaller footprint was allowed by using all 5.0 mm screws in the head of the plate. The central 95° fixed-angle screw hole is still present to allow the surgeon to use the plate as a reduction tool.

2. Sagittal plane anterior bowing begins at the first combination hole rather than more proximally. The radius of curvature is 1100 mm, which is consistent with current literature describing the average femur.

3. Intuitive and simpler aiming arm design. The insertion handle attaches at the first combination hole. The advantage is a clear radiographic visualization of the joint and the plate position on the lateral view. The disadvantage compared to the LISS is the required incision length for plate insertion via the aiming arm which is a few centimeters more (approximately 7 cm total length). The aiming arm also has slots between the holes, allowing for slightly larger stab incisions through the skin and iliotibial band, thereby easing cannula insertion.

4. Simplified screw options. The plate can be inserted using locking and nonlocking options with just two screw types: 5.0 mm VA locking screws and 4.5 mm nonlocking screws. This simplifies the scrub technicians role in surgical assistance with drill bits and screws. If desired, there are nine different screw options to choose from and to place in the modular screw racks. All 5.0 mm VA locking screws have to be tightened with 6 Nm with a T-handle with torque-limiting function.

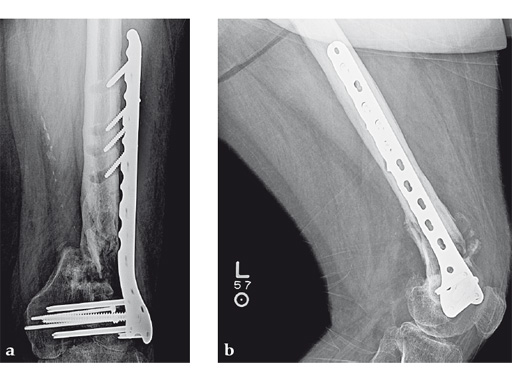

Case provided by Matthew Graves, Jackson, USA

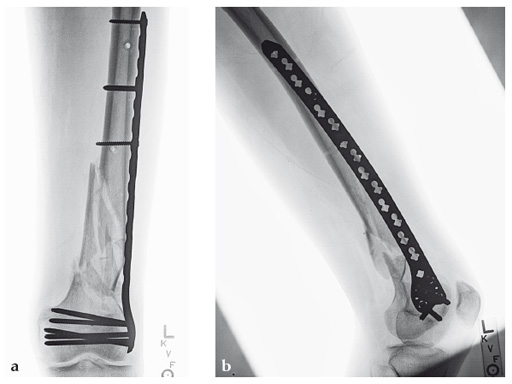

Case 1: A 30-year-old man was involved in a motor vehicle collision and sustained an isolated extraarticular multifragmentary supracondylar femoral fracture (33-A3).

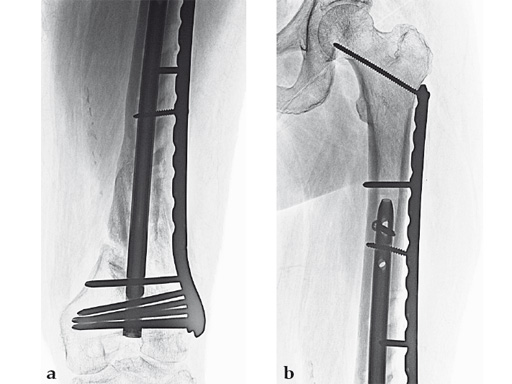

Case provided by Matthew Graves, Jackson, USA

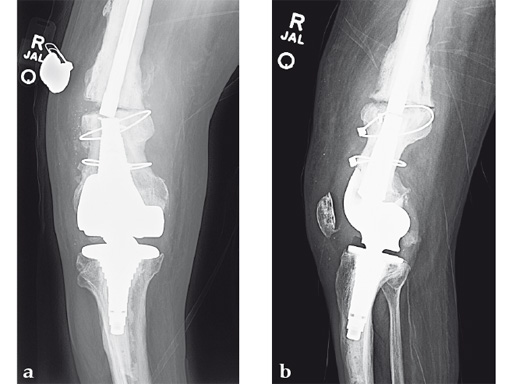

Case 2: A 69-year-old man following revision total knee arthroplasty with a megaprosthesis, requiring an osteotomy of his femoral shaft for realignment of his femoral component. The patient developed a nonunion of his osteotomy and subsequently fractured the stem of his megaprosthesis.

Surgical treatment of this nonunion consisted of compression plating using the VA-LCP Curved Condylar Plate. The arthroplasty components were stable. The proximal piece of the stem was extremely well fixed. Variable-angle locked screws were targeted between his femoral shell and stem in the distal segment allowing excellent distal fixation such that an articulated tensioning device could be attached proximally and the nonunion could be compressed and the alignment improved.

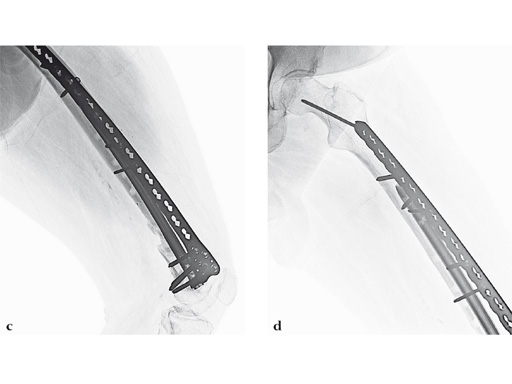

Case provided by Matthew Graves, Jackson, USA

Case 3: A 53-year-old man with hypotestosteronism, low vitamin D levels, and calcium metabolism problems. Recalcitrant atrophic nonunion of his distal femur after three surgical attempts with an extension and flexion contracture of his knee.

The VA-LCP Curved Condylar Plate was used to avoid previous enlarged screw holes and allow for stable fixation in the patient's osteoporotic distal segment. Secondary to his metabolic and mechanical problems, the decision was made to proceed with an endosteal implant and place interlocking screws through that implant from the VA-LCP Curved Condylar Plate. The combination of the retrograde/antegrade femoral nail and VA-LCP provides a very stable mechanical environment for the expected prolonged healing response.

New solutions for distal femur fracture fixation

Hazards and labeling

Due to varying countries’ legal and regulatory approval requirements, consult the appropriate local product labeling for approved intended use of the products described on this website. All devices on this website are approved by the AO Technical Commission. For logistical reasons, these devices may not be available in all countries worldwide at the date of publication.

Legal restrictions

This work was produced by AO Foundation, Switzerland. All rights reserved by AO Foundation. This publication, including all parts thereof, is legally protected by copyright.

Any use, exploitation or commercialization outside the narrow limits set forth by copyright legislation and the restrictions on use laid out below, without the publisher‘s consent, is illegal and liable to prosecution. This applies in particular to photostat reproduction, copying, scanning or duplication of any kind, translation, preparation of microfilms, electronic data processing, and storage such as making this publication available on Intranet or Internet.

Some of the products, names, instruments, treatments, logos, designs, etc referred to in this publication are also protected by patents, trademarks or by other intellectual property protection laws (eg, “AO” and the AO logo are subject to trademark applications/registrations) even though specific reference to this fact is not always made in the text. Therefore, the appearance of a name, instrument, etc without designation as proprietary is not to be construed as a representation by the publisher that it is in the public domain.

Restrictions on use: The rightful owner of an authorized copy of this work may use it for educational and research purposes only. Single images or illustrations may be copied for research or educational purposes only. The images or illustrations may not be altered in any way and need to carry the following statement of origin “Copyright by AO Foundation, Switzerland”.

Check www.aofoundation.org/disclaimer for more information.

If you have any comments or questions on the articles or the new devices, please do not hesitate to contact us.

“approved by AO Technical Commission” and “approved by AO”

The brands and labels “approved by AO Technical Commission” and “approved by AO”, particularly "AO" and the AO logo, are AO Foundation's intellectual property and subject to trademark applications and registrations, respectively. The use of these brands and labels is regulated by licensing agreements between AO Foundation and the producers of innovation products obliged to use such labels to declare the products as AO Technical Commission or AO Foundation approved solutions. Any unauthorized or inadequate use of these trademarks may be subject to legal action.

AO ITC Innovations Magazine

Find all issues of the AO ITC Innovations Magazine for download here.

Innovation Awards

Recognizing outstanding achievements in development and fostering excellence in surgical innovation.